POSCO opens new hot strip rolling mill in S. Korea

SEOUL, Oct. 31 (Yonhap) -- POSCO, South Korea's largest steelmaker, opened its No. 4 hot strip rolling mill at its Gwangyang plant that will supply sheet metal to carmakers round the world.

The steelmaking conglomerate said the new mill, located 423 kilometers south of Seoul on the country's southern coast, will churn out 3.3 million tons of steel products annually.

It said the sheet metal from the mill can be made to order to meet specific needs of customers. POSCO said the sheets can be made as thin as 1.2 millimeter or as thick as 22 mm, with the width ranging from 700 mm all the way up to 1,950 mm.

"The products made will be shipped to car manufacturers outside the country, with very little being used in the country," the company said. POSCO counts Volkswagen, Ford, Toyota and Nissan as its customers.

POSCO chairman Kwon Oh-joon said at the ceremony to mark the completion of the mill's construction that the new facility will help the steelmaker maintain and advance its global position as a supplier of top quality plates for automobiles.

The steelmaker then said its newest host strip rolling mill is noteworthy because 100 percent of the engineering involved in its construction was carried out in-house by its affiliates. This, it claimed, can enhance the overall competitiveness of the steelmaker and can open new business opportunities.

In the past POSCO, like many others in the business, had to rely on dedicated engineering companies to build specialized mills.

POSCO Engineering & Construction Co. (POSCO E&C) handled the heating furnace, rolling mill and metal winding facilities with software aspects of the plant being managed by POSCO ICT, the steelmaking conglomerate's smart business and infrastructure integration affiliate.

It said compared to other mills, the Gwangyang 4 unit has a high-tech evaporating cooling system that can better use wasted steam and comes with a versatile slab sizing press.

POSCO added that the cooling table is 30 meters longer, which can speed up the cooling process of products made. The mill, moreover uses a "pallet type" system to move finished products, compared to conventional conveyors that have been cited for causing defects in certain instances.

yonngong@yna.co.kr

(END)

-

S. Korea marks 30th anniv. of Korean Pavilion at Venice Biennale with contemporary art

S. Korea marks 30th anniv. of Korean Pavilion at Venice Biennale with contemporary art -

Artist Lee Bae captures ethereal Korean aesthetics at Venice Biennale

Artist Lee Bae captures ethereal Korean aesthetics at Venice Biennale -

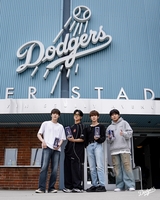

Ateez member Yunho throws first pitch at MLB match between Dodgers, Mets

Ateez member Yunho throws first pitch at MLB match between Dodgers, Mets -

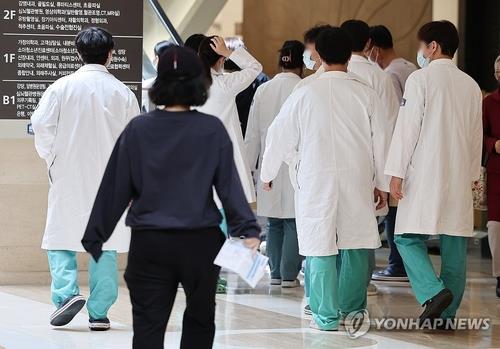

Gov't likely to accept university chiefs' request to lower med school enrollment quota

Gov't likely to accept university chiefs' request to lower med school enrollment quota -

S. Korea supports resolution backing U.N. membership of Palestine

S. Korea supports resolution backing U.N. membership of Palestine

-

Artist Lee Bae captures ethereal Korean aesthetics at Venice Biennale

Artist Lee Bae captures ethereal Korean aesthetics at Venice Biennale -

S. Korea marks 30th anniv. of Korean Pavilion at Venice Biennale with contemporary art

S. Korea marks 30th anniv. of Korean Pavilion at Venice Biennale with contemporary art -

Gov't likely to accept university chiefs' request to lower med school enrollment quota

Gov't likely to accept university chiefs' request to lower med school enrollment quota -

Experts see possibility of N.K. conducting nuclear test before U.S. presidential vote

Experts see possibility of N.K. conducting nuclear test before U.S. presidential vote -

Details of meeting between Yoon, opposition leader undecided: presidential office

Details of meeting between Yoon, opposition leader undecided: presidential office

-

U.S. will take steps for three-way engagement on nuclear deterrence with S. Korea, Japan: Campbell

U.S. will take steps for three-way engagement on nuclear deterrence with S. Korea, Japan: Campbell -

(LEAD) Hybe to file complaint against sublabel executives over internal conflict

(LEAD) Hybe to file complaint against sublabel executives over internal conflict -

S. Korea reports highest suicide rate, ultra fine dust level among OECD nations: data

S. Korea reports highest suicide rate, ultra fine dust level among OECD nations: data -

U.S. sent ATACMS missiles to Ukraine following Russia's use of N.K. missiles: White House

U.S. sent ATACMS missiles to Ukraine following Russia's use of N.K. missiles: White House -

Looming weekly closure of major hospitals feared to worsen medical service crisis

Looming weekly closure of major hospitals feared to worsen medical service crisis